[As Seen on The Punch] Waste to Resource: ChopValue's Circular Economy Model

![[As Seen on The Punch] Waste to Resource: ChopValue's Circular Economy Model](http://chopvalue.com/cdn/shop/articles/Newsroom_Banner_1920_x_1006_54_{width}x.png?v=1736463243)

Bamboo, a hallmark of Bali’s ancestral forests, often features prominently in various local businesses. Orin Hardy who directs PT Bamboo Pure and co-founded Bamboo U, while PT Bamboo Pure is a construction company specializing in bamboo, and Bamboo U serves as a hub for education. Orin’s passion lies in creating businesses that fulfill human needs while synchronizing with the environment.

Orin’s journey with bamboo is rooted in tradition, a legacy that has been in his family for generations, where the versatility of this natural material has long been celebrated. Along this path, Orin discovered that true impact lies not only in the use of materials but in the way they complete their cycle–a perspective matching the principle of a circular economy, where waste becomes obsolete. Confronted by Indonesia’s mounting waste challenges, Orin brought ChopValue to the country, envisioning a new lifecycle for sustainable resources, one where materials go beyond their initial purpose and reveal unexpected, enduring potential.

![]()

THE CHOPVALUE CONCEPT

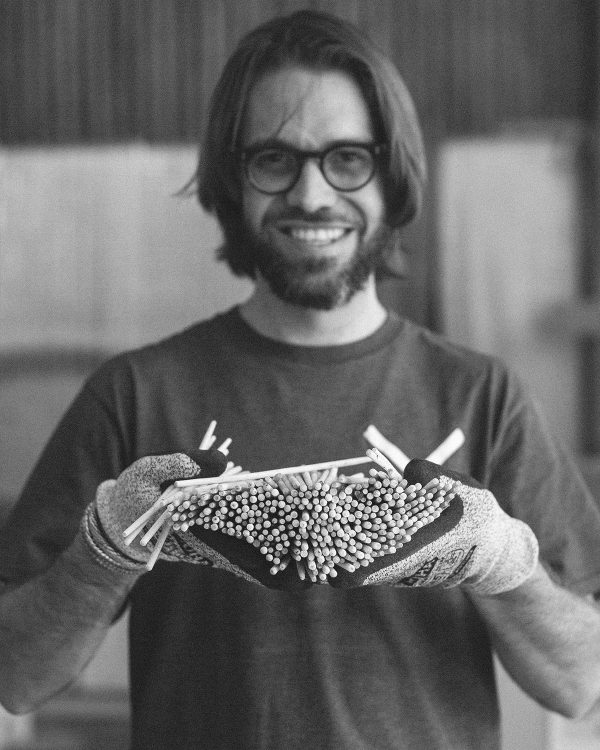

ChopValue is an innovative venture that puts the circular economy into practice. Founded by Felix Böck, a Gecrman timber and bamboo engineer, the project ignited with a provocative question: Can the fleeting, thirty-minute lifespan of chopsticks be transformed into a symbol of sustainability? Felix recognized that although bamboo chopsticks are organic, their environmental footprint extends far beyond their brief utility.

ChopValue’s mission is to reinvent waste streams into valuable, high-quality products, thereby giving them a second life. What began as a bold experiment in Canada is now capturing global interest with 150 microfactories in development.

GLOBAL INNOVATION, LOCAL TRANSFORMATION

When Orin first encountered ChopValue, it was in a setting far removed from Bali. He visited Felix’s original Microfactory in Vancouver and discovered an ambitious vision for global expansion. Instantly, his curiosity was piqued: could this innovative model seamlessly align with Indonesia’s landscape? With 15 years of experience in bamboo, he saw ChopValue’s concept as a sophisticated extension of their craft.

The initiative plans to establish 25 Microfactories across Indonesia, particularly in bustling urban centers, to gather used chopsticks from key partners such as restaurants and transform them into forward-thinking products. ChopValue is the latest venture that looks for more sustainable ways to use bamboo.

![]()

TURNING WASTE INTO OPPORTUNITY

Bali’s scenic charm masks a pressing issue: the island faces major challenges because it doesn’t have a waste management system. Trash burning and plastic litter are prevalent, causing the urgent need for action from both the government and private sector. ChopValue Bali addresses this issue by repurposing a significant number of discarded chopsticks and satay sticks. With over 220 collection partners across the island, the company collects these used chopsticks and transforms them into new products, showcasing how small actions, such as properly disposing of chopsticks, can lead to substantial environmental benefits.

![]()

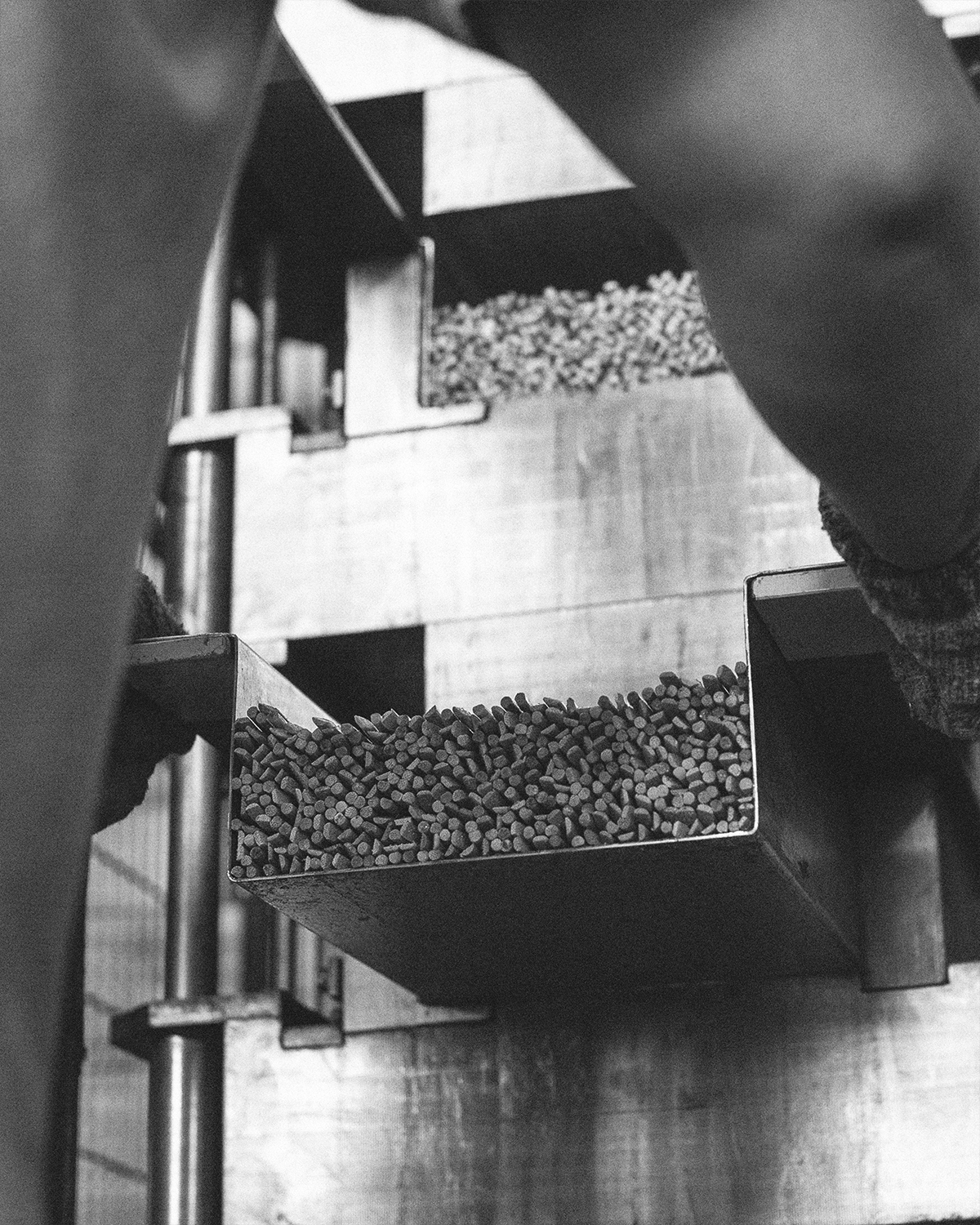

THE INSPIRING MICROFACTORY SETUP

The most captivating aspect of introducing this concept to Bali has been the synergy between skilled precision work and cutting-edge technology. The global benchmarks set by ChopValue share a powerful truth: exceptional manufacturing and quality standards do not require vast, multimillion-dollar facilities. Instead, the micro-factory model demonstrates that efficiency and innovation can thrive in smaller, localized setups. This approach not only encourages sustainability but also empowers local communities to be part of the solution, proving that meaningful change can start on a small but global scale.

INNOVATIVE RESOURCE

Within Bali’s well-known craftsmanship, traditional arts are declining because of the changing markets. ChopValue Bali steps up to the plate with a vision of turning waste into valuable resources that mix modern technology with age-old techniques. This initiative helps to preserve Bali’s artistic heritage and also serves as an inspiration for future artisans.

The global vision is further developed by the locals and ChopValue is where this approach to redefining waste is shared. In Ubud, the company’s Nanofactory shows how Bali’s artisanal legacy can flourish side-by-side with cutting-edge advancements. Visitors don’t only get to observe innovation but they can engage hands-on, personalizing creations through laser engraving–inscribing names, drawings, or memories on keepsakes while supporting a circular economy.

![]()

TRANSFORMATIVE IMPACT

ChopValue’s influence in Bali is transforming waste management through innovative practices. Collecting 280 to 300 kilos of chopsticks weekly from over 230 sites, they convert discarded materials into high-quality products, such as tables and chopping boards. This process not only prolongs the life of these resources but also helps lessen the carbon footprint.

In the past year alone, they have upcycled 6.8 million chopsticks in Bali, contributing to a global total of over 183 million. Each micro-factory, including the one in Bali, can process up to 24 million chopsticks annually, promoting a shift towards a circular economy. With plans to establish 25 micro-factories across Indonesia, ChopValue is raising industry standards for resource recovery and sustainability.

Through a circular economy model, ChopValue addresses the country’s resource challenges while creating jobs and driving industry growth. Their team is dedicated to enhancing Indonesia’s future by embedding best practices into their operations and promoting future-proof living in all aspects of life.